The mold alignment unit is also called the alignment gu […]

The mold alignment unit is also called the alignment guide device of the mold blade. In order to ensure the alignment of the upper mold and the lower mold and shorten the preparation time, according to the requirements of product accuracy and production quantity, there are mainly the following five types of mold alignment units:

(1) Non-guided type: When the mold parts is installed on the punching machine, the pairing of its blades is directly performed without the use of guiding devices.

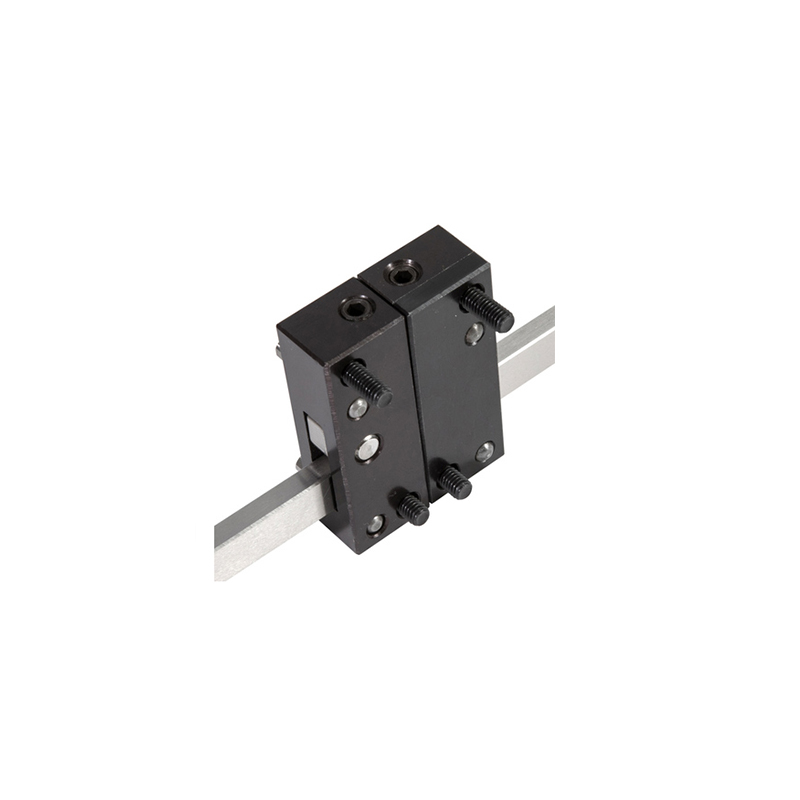

(2) Outer guide type: this type of device is the most standard structure. The guide device is installed on the upper and lower mold bases without passing through the templates, and is generally called the mold base type.

(3) External guiding and internal guiding combined type (1): This type of device is the most commonly used structure for continuous molds. An internal guiding device is installed between the punch fixing plate and the pressing plate. The combination of the punch and the die utilizes a fixed pin and an outer guide device. Another function of the inner guiding device is to prevent the pressure plate from tilting and protect the small punches.

(4) Combined use of outer guide and inner guide (2): This device is a high-precision and high-speed continuous mold structure, and the inner guide device penetrates the punch fixing plate, the pressing plate and the die fixing plate, etc. . The inner guiding device itself also has the function of aligning and protecting small punches. The main function of the outer guiding device is to get a smooth goal when the mold is disassembled and installed on the punching machine.

(5) Inner guide type: This structure does not use outer guide device. The inner guide device penetrates the punch fixing plate, the pressing plate and the die fixing plate, etc., to correctly maintain the positional relationship of each plate for protection shower.