(1). When shape punching (cutting) or continuous punchi […]

(1). When shape punching (cutting) or continuous punching, in order to guide the width direction of the processed material and obtain the correct feeding pitch, a guide unit is used.

(2) The guiding device in the width direction of the strip, the guiding methods are: (A). Fixed plate guide pin type, (B). Movable guide pin type, (C). Plate tunnel guide type ( Single plate), (D). Plate guiding type (two pieces), (E). Lifting pin guiding type (movable type, fixed type and both.

(3) The guide device for starting and stopping has two forms: (1). Slider type, (2). Movable pin type, etc. The main function is to locate the material at the initial starting position of the mold.

(4) The feeding stop device can accurately determine the feeding pitch. It is mainly used for manual feeding. Its forms are: (A). Fixed stop pin, (B). Movable stop pin, (C ). Side cutting stop mode, (D). Hook stop mechanism, (E). Automatic stop mechanism.

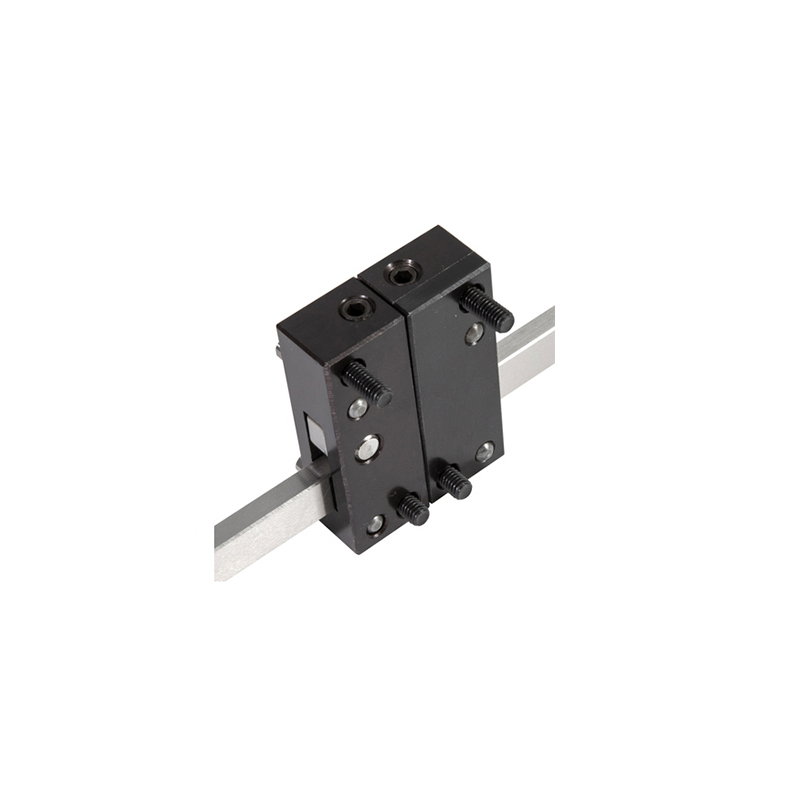

(5) Side-pushing material guide mechanism, the material is pressed to one side during the stamping process, which can prevent the material from snaking due to the difference between the width of the strip and the width of the guide.

(6). Blank material position positioning and guiding mechanism, its forms are: (A). Fixed pin guide type (using the shape of the blank), (B). Fixed pin guide type (using the hole of the blank), (C). Guide plate (for large parts), (D). Guide plate (integrated), (E). Guide plate (divided).