(1). Design of punching die The key items that should b […]

(1). Design of punching die

The key items that should be considered in the shape design of the punching die are: A. The life of the die and the shape of the escape angle, B. The shear angle of the die, and C. The division of the die.

(A). Mold life and shape of escape angle: This design is a very important matter. If the design is not correct, it will cause punch damage, blockage or floating of punching chips, and occurrence of burrs.

(B). Shear angle of the die: In order to reduce the punching force when the shape is punched, the die can be designed with a shear angle. When the shear angle is large, the punching force will be reduced greatly, but it is easy to cause the product to bend and deform .

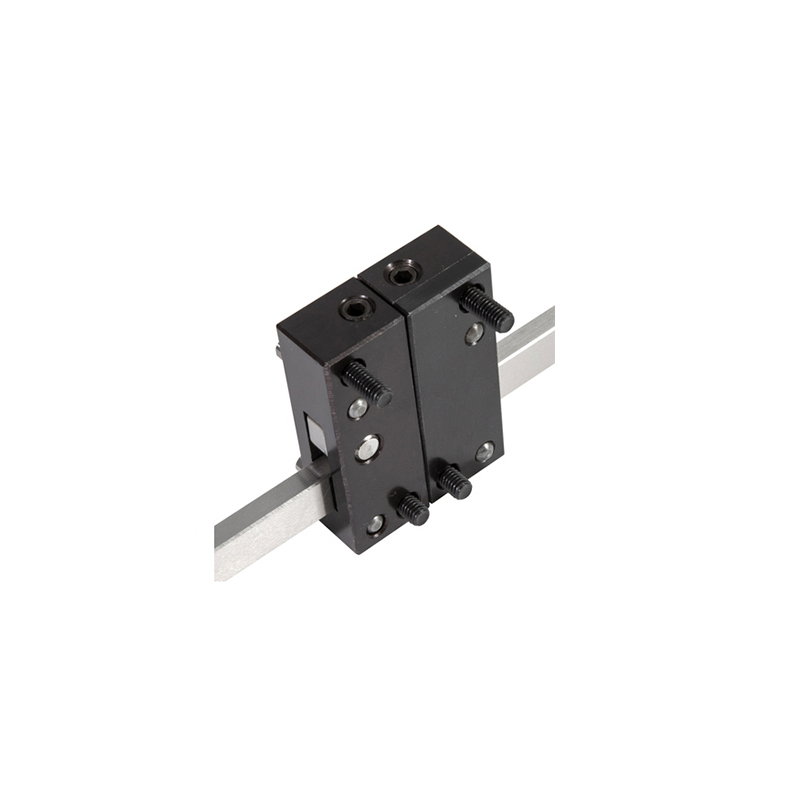

(C). Dividing of the concave mold: The concave mold must be subjected to finishing processing such as forming and grinding. Because of its concave shape, the grinding tool is not easy to enter, so it must be divided.

(2). Design of bending die

The design of the concave mold for bending is to prevent springback and excessive bending. The shape of the concave mold for U-shaped bending is a combination of double R and straight part (30 degrees inclination), preferably approximately R shape. The shape of R part should be polished after forming grinding or NC electric discharge machining.

(3). Design of drawing die

The corner shape and escape angle shape of the drawing die are very important design items. The shapes and characteristics of the corner and escape corner are as follows: the drawing die is easier to draw when the R angle value is large, but it also produces the surface of the drawn product. Wrinkles occur, and the thickness of the side wall of the drawn product is greater than the thickness of the plate. When drawing thick plates and difficult ejection, the R value of the die should be small, about 1-2 times the thickness of the plate. Generally, most of the drawing parts of the drawing die of the cylinder and the square tube are made straight, in order to prevent For purposes such as burning, destroying the lubricating oil film and reducing the ejection force, it is advisable to have an escape part (stage-shaped or push-pull-shaped) design under the straight section. Especially in the case of shrinking processing, this straight section must be as small as possible.